Productivity, Automation, and an Aging Workforce

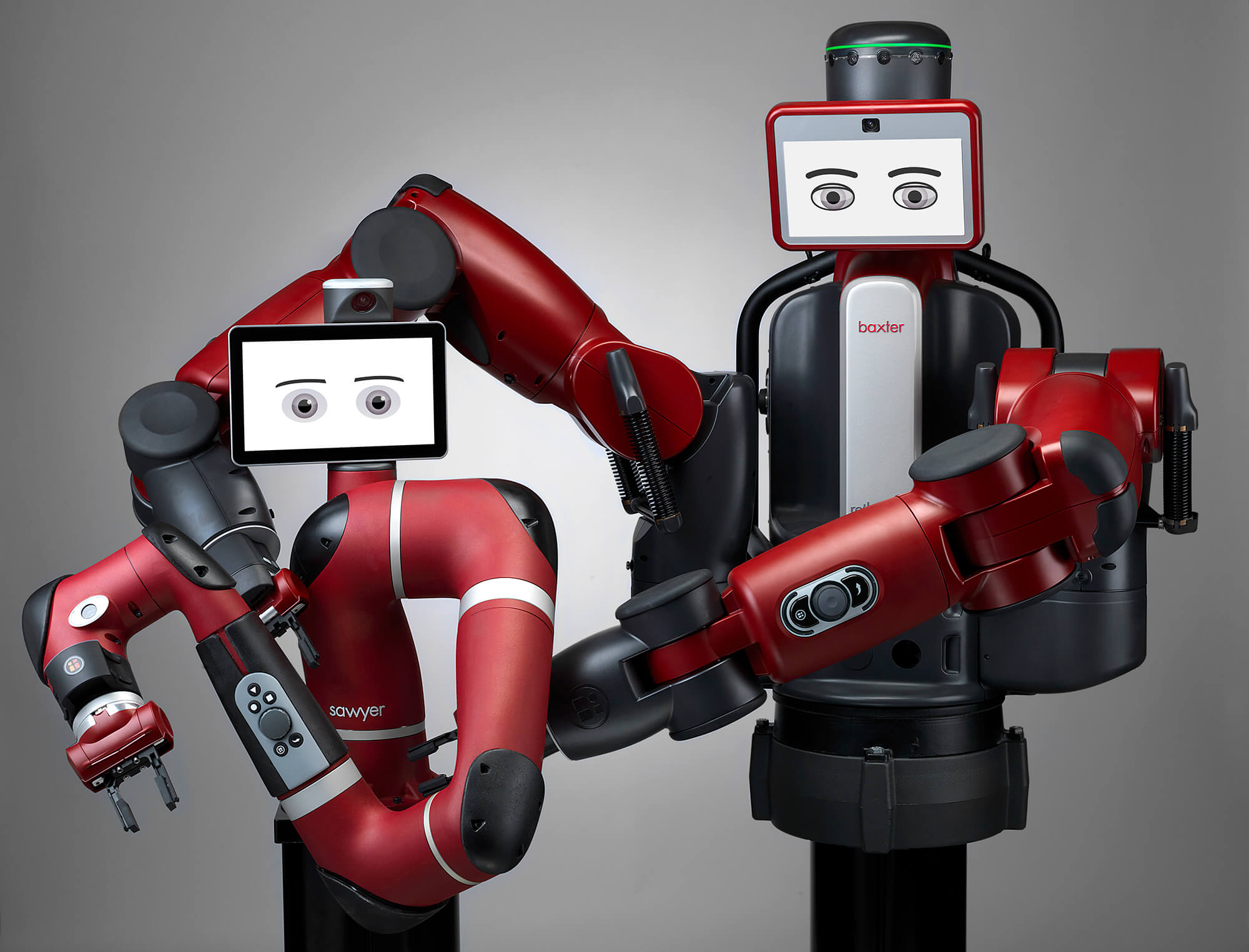

The Universal Basic Income movement is based on a belief that widespread adoption of rapidly advancing automation technology will cause a “robot apocalypse” in the job market. The automation in question ranges from what most people perceive as “robots” such as rethink Robotic’s Baxter, as shown above, to autonomous vehicles to purely software AI ‘bots like the automated systems you often chat with when you try to fix a computer or network issue online — or when you call your credit card company and have to fight through a Roman legion of them to get a live person!

One of the core premises of the Universal Basic Income (UBI) movement is the falling cost of automation relative to labor. The thinking in the UBI world is that the costs of these robots is falling so fast and the capability is improving so much that real workers in many professions simply won’t be able to compete. The venture investment world feeds off tech manias like this. We’ve seen this movie before, in the dot.com bubble that popped around the turn of the century and most recently in clean tech, as Bradford Cross eloquently summarizes in a recent blog:

….. In cleantech, there was a lot of the hubristic knight-in-shining-armor attitude that is characteristic of tech manias. In AI over the past couple years, we’ve started to see self-aggrandizing AI ethics committees and the like, people talking about what to do when the robots take all the jobs, and so on. It’s the attitude that those working in and around AI are now responsible for shepherding all human progress just because we’re working on something that matters. This haze of hubris blinds people to the fact that they are stuck in an echo chamber where everyone is talking about the tech trend rather than the customer needs and the economics of the businesses. This toxic reality distortion field is what allows the mania to draw large numbers of smart but self-important people into the impending web of doom.

Now, while I completely agree that there will indeed be an investment bubble that will eventually pop around AI, robotics, and autonomous devices, that doesn’t preclude there being a lot of money made, new enterprises created (along with the jobs they bring), and changes in our workforce along with the products that those new enterprises bring to market in the interim. In the end, it’s all about “the economics of the business”, just as Bradford says, but is that truly a robot apocalypse in the making? Let’s look at some examples of the sorts of jobs that many big-picture people think will be automated out of existence in the coming decade, starting with the manufacturing workforce.

As I noted in my previous column, the workforces in every economically developed country on the globe are aging – and shrinking – even as GDP growth pushes the market for goods and services to ever greater heights. Big company executives with global production footprints are planning now how they will address a workforce in the 2020s that is both older and shrinking. For the past 20 years, the answer has been to chase labor around the globe in LCCs (Low Cost Countries) from China to Mexico. However, that era may be at an end with global wages rising and Chinese net production costs passing those of the US. The advanced robotics that many fear will take jobs may actually be the enabler to keep those jobs in higher cost countries instead.

Consider this: The present US autoworker wage, with full benefits, vacation, overtime, etc., ranges from $48-$58/hr. This is on the high end of US manufacturing wages. In Mexico, arguably the global auto industry’s favorite LCC, where 9 of the last 11 new auto assembly plants built in North America have landed, that wage is $8-$10/hr. The US, or European, worker is older on average and likely to be less physically capable. As the standard of living rises in Mexico and other LCCs, we can expect the wage gap to close measurably.

At the same time, we are now at the dawn of low-cost collaborative robots (also called cobots) that can safely work side-by-side with humans, as opposed to existing industrial robots that require extensive safety equipment and cages and can only take on tasks that do not require human intervention of any sort. All of that safety gear and the need to isolate the robot drives the cost of conventional automation through the roof, on the order of $100s of thousands per robot cell, which is why LCCs can compete with conventional robotics, despite the logistics costs of shipping from those countries. Sales of conventional robotic automation like this have continued to climb slowly for the past 20+ years, but there appears to be no sudden expansion on the horizon for this class of industrial robot.

The cobot industry, in sharp contrast, is presently projected to undergo explosive growth over the next 5 years, with global sales going from ~$110M USD to over $3B between now and 2022. What makes cobots so compelling is their cost, and not just the initial cost, but rather the total installed, up, running, and doing cool things cost. A cobot can cost as little as the projected $10,500 for Franka Emika, up to the $29-$35k for Rethink Robotics’ Sawyer or Universal Robotics’ UR5. More importantly, because they are inherently designed to work with humans, all of that expensive safety equipment, and the plant floor area that comes with it, are not needed. The net of this is that the cost of a cobot is largely the cost of the robot itself, whereas with conventional robotics, the cost of the basic robot is just the getting started point! Any way you slice it, you don’t need a Deloitte accountant to tell you that the equivalent hourly wage for a robot this cheap is in the $1/hr range, and the costs appear to be falling.

The very premise of a cobot is the “co-“ part – it is made to work WITH humans, not totally in place of them. The fundamental physics of how much and how fast one of these cobots can lift is governed both by electric motor capability, which really hasn’t moved a great deal over the last 20 years (nor is it projected to in the foreseeable future), and by the need to not be so powerful that it could pose a threat to humans through accidental contact. So, you need a human present for some portions of the assembly task, especially if it involves a heavy lift. This is true even when the heavy lift is mechanically augmented, because if you replace that human-controlled mechanical augmentation with an industrial robot of similar power, now you’ve moved right back into the cost realm where LCCs live.

Now, if you have your US, Japanese, or Western European assembly line worker making ~$50/hr, supplemented by two or three low-cost cobots at ~$1/hr so that his or her cell gets as much work done as 3-5 workers would in an LCC without the automation, the cost of production starts getting pushed as much by shipping logistics costs (not to mention shipping carbon footprint) as it does by labor cost. At that point, why would you move production to an LCC with its attendant language, logistics, and legal barriers? Cobots can make a higher-cost, older workforce competitive with LCCs, saving jobs in the process rather than eliminating them.

On top of that, we haven’t even considered how worker augmentation devices are advancing, right up to full-on exoskeletons like the Panasonic Power Loader or the 42-odd exoskeleton-like devices now being placed into service as medical rehabilitation aids. It’s a short jump from medical rehab to getting 50+-year-old knees and backs through a day on the production line comfortably. Nor have we talked about how many jobs will be created in the process of growing the cobot market to $3B from its current tiny beginnings.

The bottom line is that, contrary to the UBI movement’s contentions, the coming “robot apocalypse” can actually both save jobs and create jobs in the economically developed world, especially here in the US, where we’ve barely scratched the surface on the application of robotics to manufacturing. Next week, I’ll address how the rise of autonomous vehicles, especially commercial trucks, might affect jobs that use drivers today.

Images courtesy of Rethink Robotics, Inc.

Join the Catalyst Monitor

Join our community, where we push out regular insights to help maintain situational awareness on technological and socioeconomic trends.