Enabling Renewable Energy

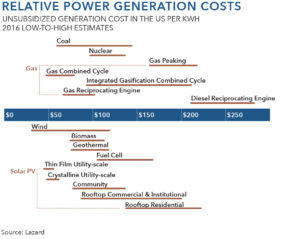

Solar and wind power technologies are mature. On a pure power generation basis, wind and solar cost about the same to generate as gas, coal, and nuclear power. Battery technology is the remaining piece of the puzzle for the mainstream economic viability of renewables. A power storage solution is needed to offset the inherent variability of renewables that depend on sun or wind. When storage solutions become cost-efficient at scale, we can anticipate a dramatic increase in the fundamental economics and use of renewables. Current grid storage battery technology has historically not been efficient or cost-effective enough to enable renewables to truly compete with traditional energy production.

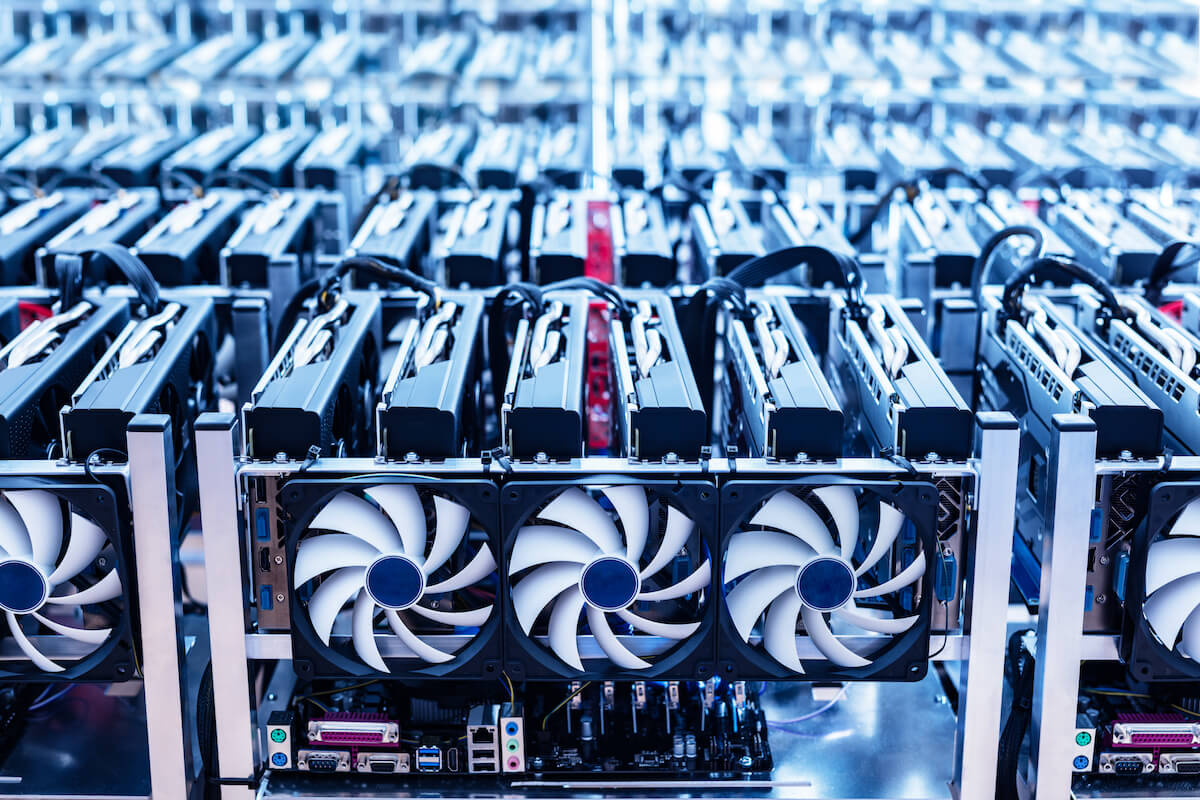

This is all about to change, thanks to significant advances in battery technology. Batteries are the critical path towards the significant expansion of renewable energy production and use. Rapid advances in this field have occurred over the past five years because of electric vehicles, which have created an important incentive for large companies to invest heavily in battery technology. Companies such as Tesla and others have invested billions in battery research to increase the range of electric cars. Until this economic incentive was introduced, battery research had been relegated to “special project” status within companies and research institutions. Now that advancements in battery technology determine the success of important companies in as large a market as automobiles, resources have surged into the field.

As just one example of the capital and resources that are flowing into this space, Tesla along with Panasonic and other partners will collectively invest about $5 billion in the lithium-ion battery “Gigafactory” in Nevada. The facility will contain around 15 million square feet on multiple levels, and according to Tesla CEO Elon Musk, “The Gigafactory, when it’s complete, will have the biggest footprint of any building in the world.” Daimler AG, Dyson, LG Chem, Fortum Oyj, and other companies are also making significant investments in battery technology, which are all serving to advance the core technologies that will support renewable power generation.

In addition to these investments, the public sector has also been involved in funding research and development efforts. The 2009 American Recovery and Reinvestment Act-better known as the stimulus package-included $2 billion in grants for manufacturing advanced batteries, along with tax credits to cover 30 percent of the cost of a battery manufacturing plant, bringing the total direct investment in batteries to $2.4 billion. The same legislation also included $7.5 billion in authorized loans for advanced vehicle manufacturing technology and $16.8 billion for energy efficiency and renewable energy, all of which include battery technology.

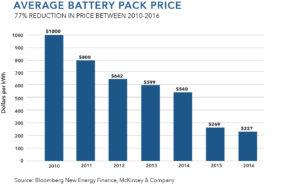

Batteries are the key constraint towards both the economic viability of renewable power generation and the consumer acceptance of electric vehicles. Decreases in cost and increases in efficiency will allow more cost-effective energy storage systems for the home and the grid and will allow electric vehicles to travel farther per charge. The measurement we use for the cost efficiency of batteries is cost per kiloWatt-hour (kWh-the W is capitalized because it is named after the inventor James Watt). A Watt-hour is the amount of electricity that is consumed by a circuit using one Watt of power for one hour, and is the same measurement we see on light bulbs and household utilities.

Both public and private sector research efforts have resulted in significant increases in battery efficiency. According to Bloomberg New Energy Finance, the average battery pack price across the industry has decreased from around $1,000/kWh in 2010 to $227/kWh in 2016, a 77 percent decline. These costs are projected to decline even further to $190/kWh by the end of the decade, and below $100 per kWh by 2030.

Tesla is ahead of this trend. In 2008, Tesla’s batteries cost around $690 per kilowatt-hour, well below the industry average even a decade ago. On an analyst call in April of 2016, a Tesla executive reported that their costs were already below $190/kWh, significantly ahead of the industry average. Tesla’s Gigafactory, which we mentioned previously, is designed to further reduce these costs by 35 percent once operational, so we may see further significant decreases in the near future.

It is unclear exactly what price point will represent the inflection point that leads to mainstream adoption of both electrical vehicles and grid storage systems. Many industry analysts project that a price point around $150/kWh will have a galvanizing effect, incentivizing broad adoption.

The migration of these technologies from electric vehicles to grid storage batteries has already begun. Tesla itself has been building grid storage batteries since 2015. Analysts at Credit Suisse have projected that around one-third of Tesla’s battery production by kWh volume will be toward energy storage systems in 2020. Bloomberg New Energy Finance projects that the cumulative deployment capacity for the energy storage market will grow from 6 gWh in 2015 to 29 gWh in 2020 and 81 gWh in 2024, a 1,250 percent increase over the 10-year period.

Energy density for size-efficient batteries is extremely important for electric vehicle development, while cost and storage capacity are more important for grid storage batteries. Increases in all of these areas are possible with lithium-ion technology, but researchers are also focused on new materials, which if realized could change the paradigm even further.

The lithium-ion battery, the current standard for both electric vehicles and consumer electronics, has made significant gains. There are three basic parts to a battery: two terminals called the anode and the cathode, and the electrolyte that separates the terminals. Rechargeable lithium-ion batteries traditionally use a lithium metal oxide for the cathode and a graphite layer for the anode, a design that has proven to be extremely effective but will eventually reach the limits with current materials.

Within the lithium family, researchers are exploring lithium-air, lithium-sodium, lithium-metal, and solid-state lithium-ion technologies. Lithium-air batteries, for example, would use oxygen as the oxidizer, drastically reducing cost and increasing longevity. Beyond lithium, there have been advances in magnesium, aluminum-air, and sodium-ion batteries, as well as graphene supercapacitors, microbatteries, and a number of other developments. Researchers are also exploring ways to completely re-imagine the battery itself in order to reduce fire hazards, overheating, and toxic waste.

We may see battery technologies branch between those that are most applicable to vehicles (higher energy density) and those better suited for grid storage (lower cost per capacity). For example, chemists at the University of Waterloo have developed zinc-ion batteries that are long-lasting, safe, and cost half the price of current lithium-ion batteries. Zinc-ion batteries tend to be large and have lower energy density than lithium-ion batteries, but could have potential grid storage applications due to their cost and safety.

Regardless of which core technology emerges, batteries are incredibly important for the widespread adoption of renewable power generation system. As solar and wind technologies have already reached the point of maturity, battery technology is our primary focus to understand the directionality and timing towards the emergence of the power catalyst.

Join the Catalyst Monitor

Join our community, where we push out regular insights to help maintain situational awareness on technological and socioeconomic trends.